Rajiv S. Risbud

Rajiv a B. Sc Chemistry Graduate and has completed Post Graduate in Management.

He has rich experience of working in companies like Reliance Industries, Asian Paints PPG Ind Ltd, Marico Industries and Kalyani Steels for about 15 years.

During these 15 years, he worked across different practises like Quality Control, Marketing and Sales & Service.

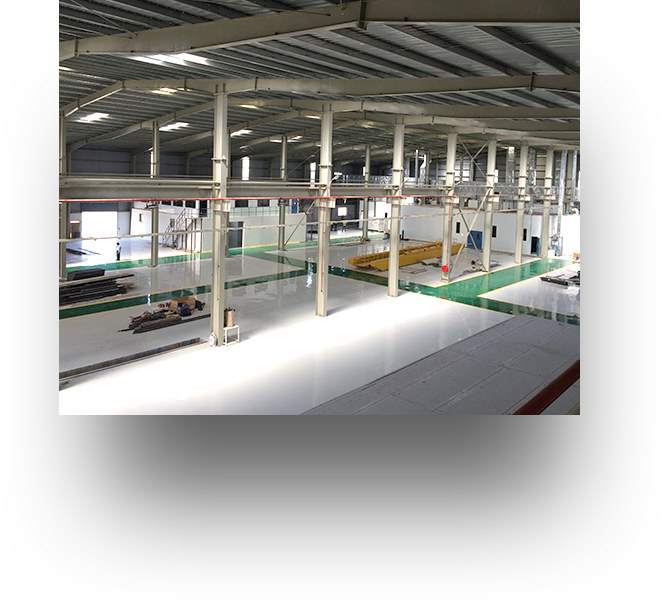

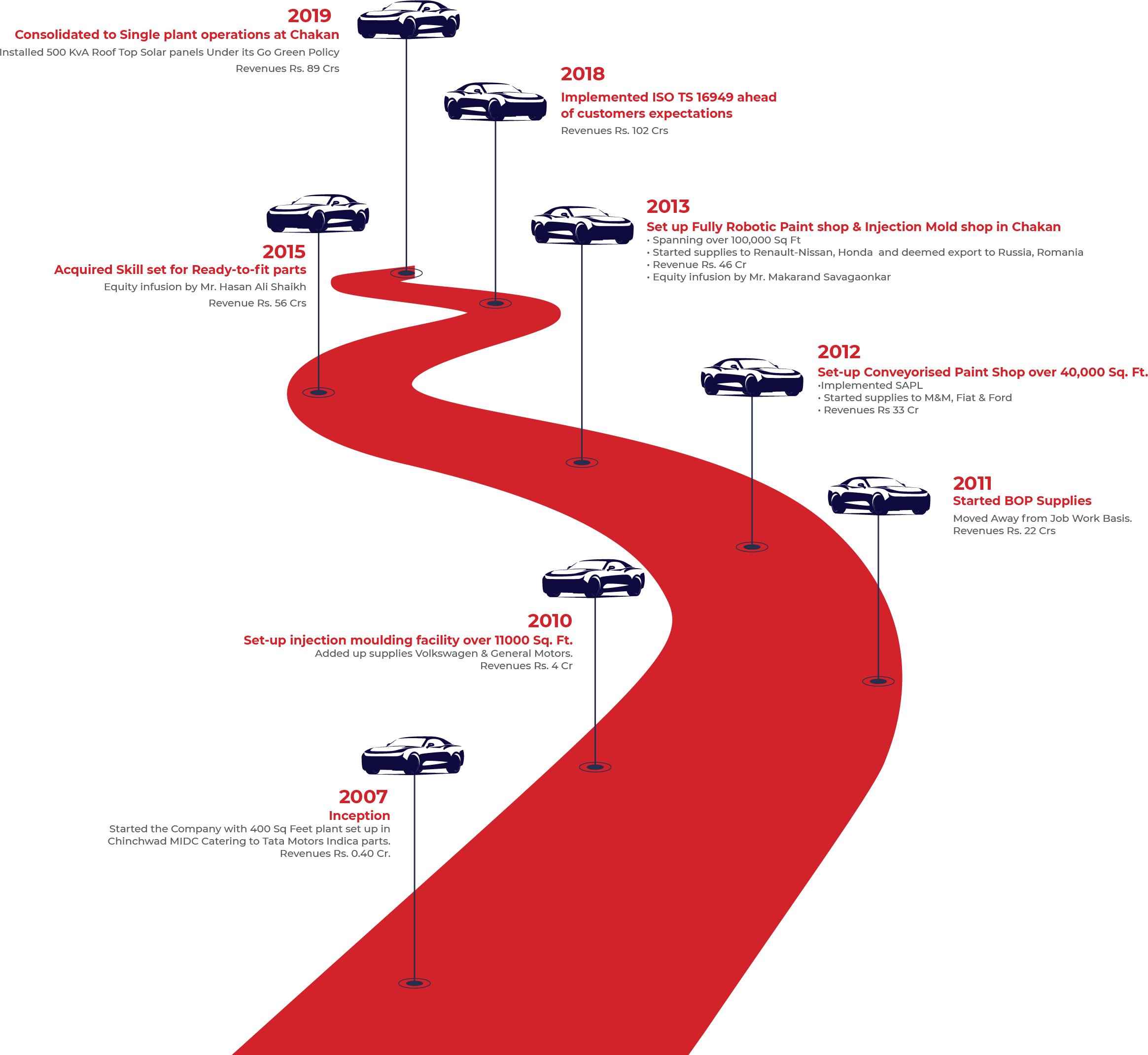

Founded SAPL in 2007 with a humble beginning and 400 sq ft & 0.4 Crores of revenues in a workshop and started painting plastic components.

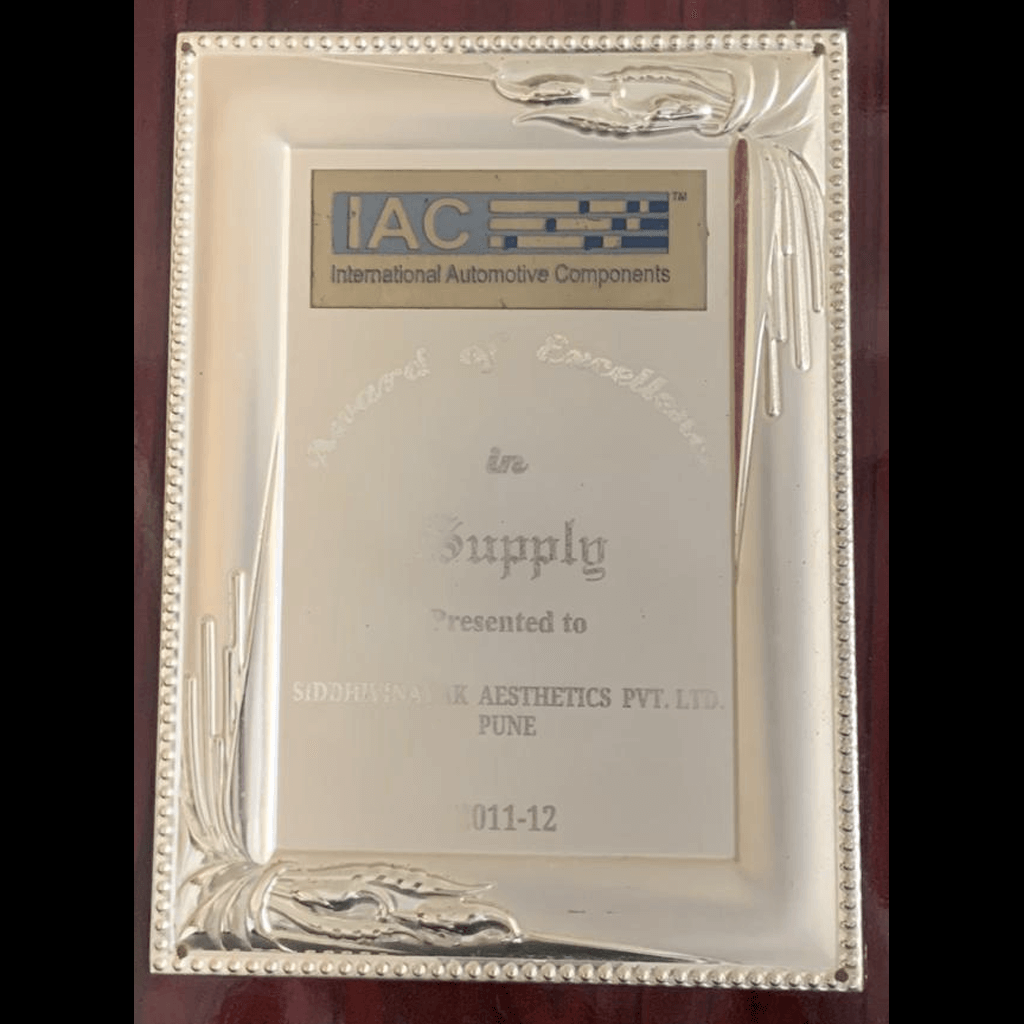

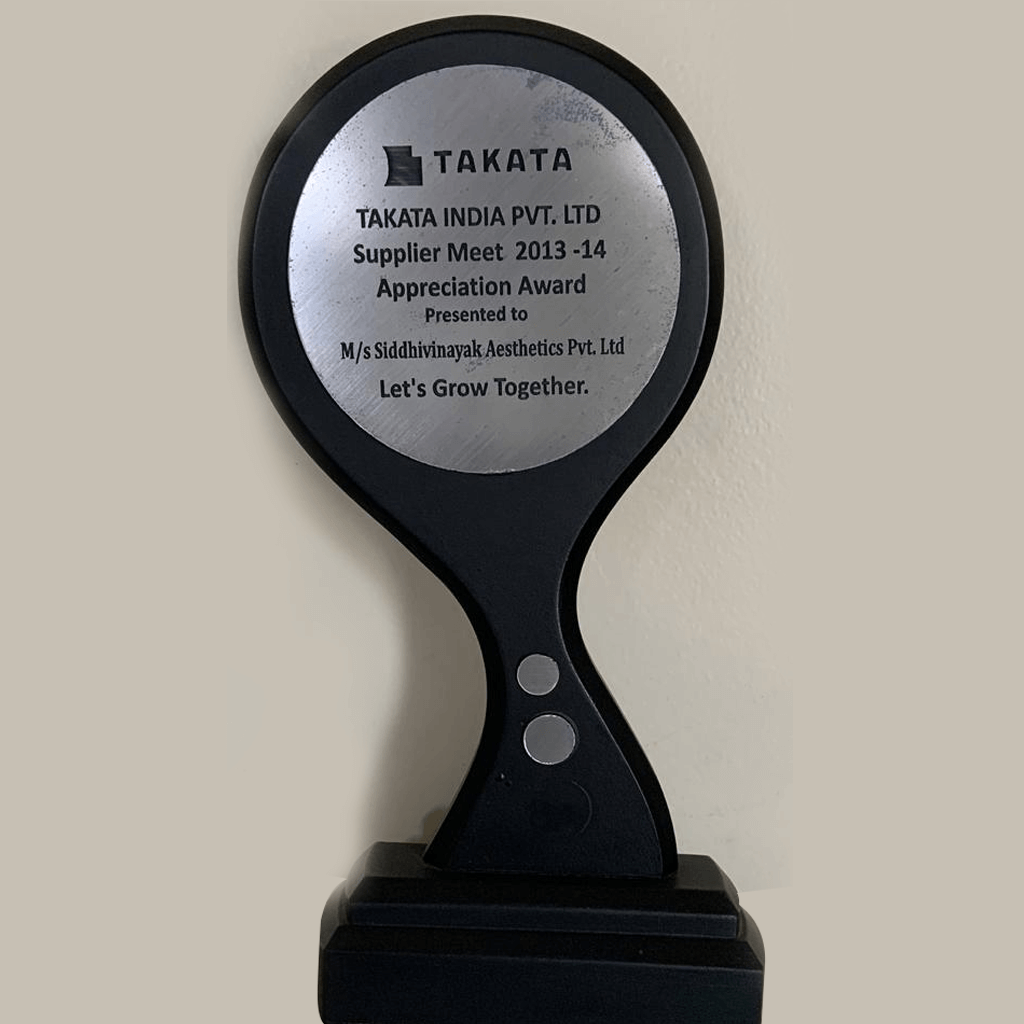

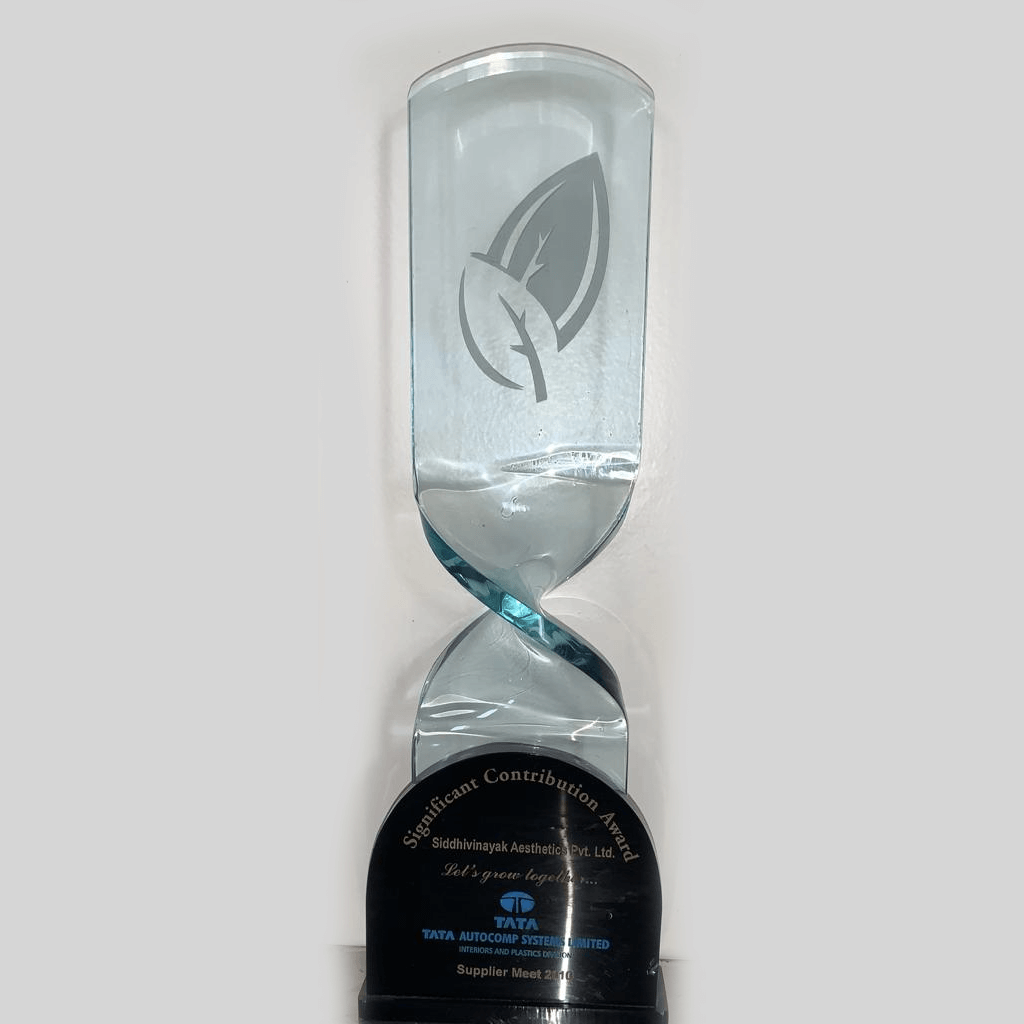

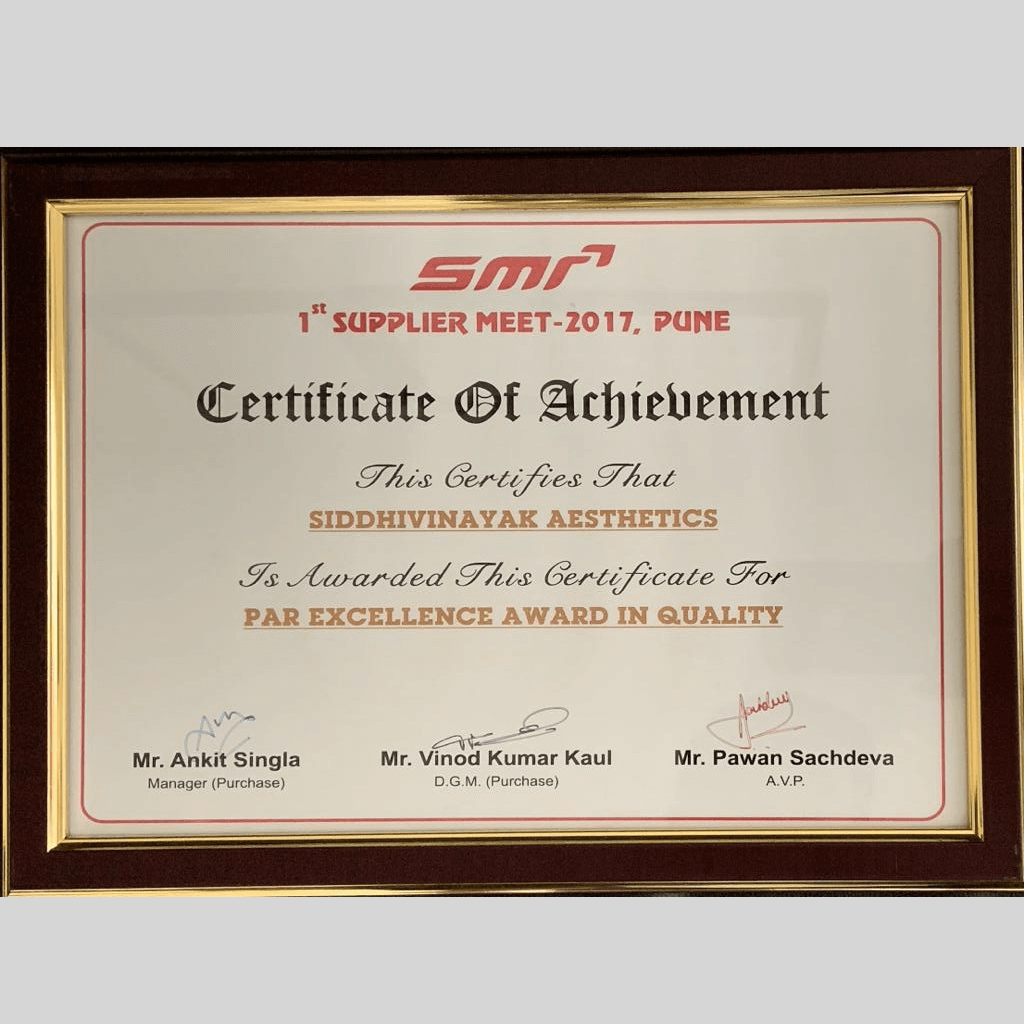

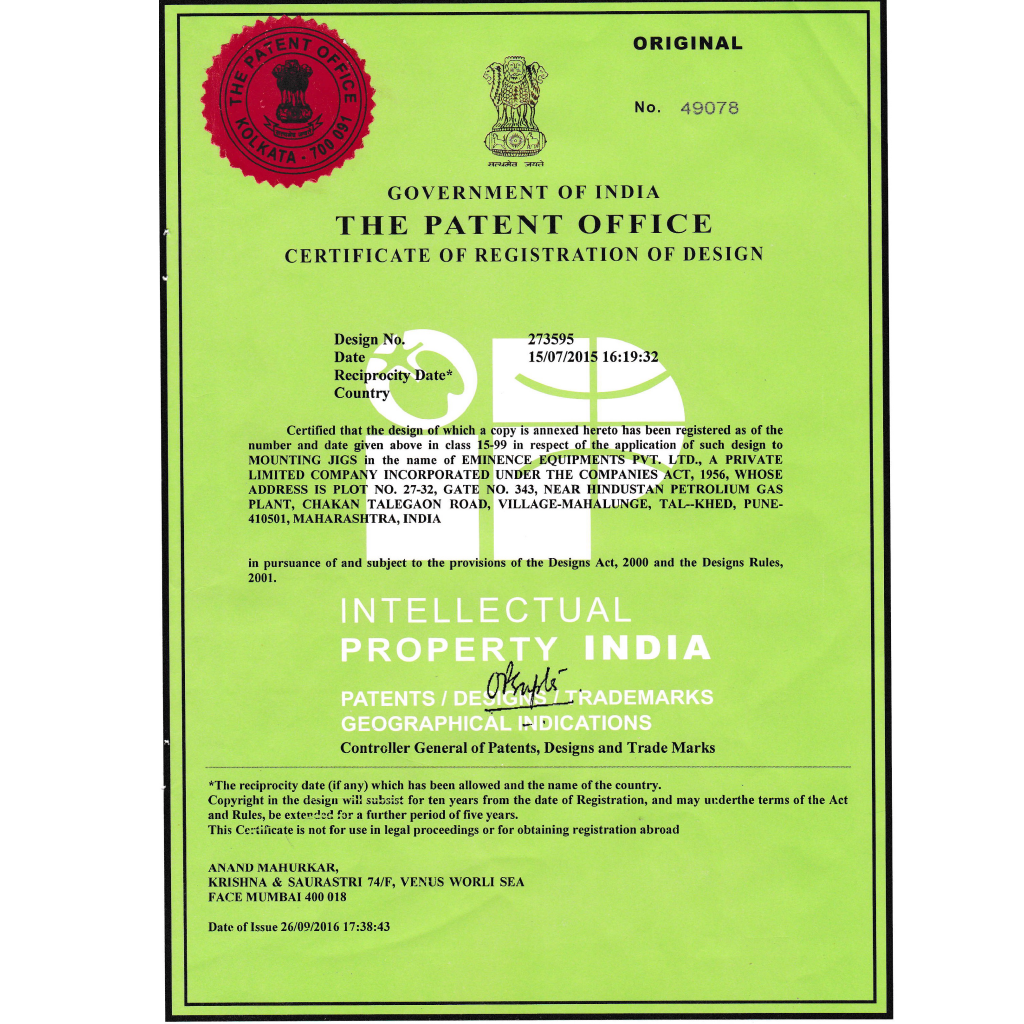

Along with Mr. Mayuresh Biware, spearheaded SAPL to a Rs. 100 Cr automotive components manufacturing company within 12 years of inception.

Currently looks over Marketing, Sales and Commercial practises at SAPL